The AI Revolution in Manufacturing

The manufacturing and industrial world is going through an exciting change. From traditional assembly lines to modern smart factories, companies are now using AI tools for the manufacturing industry to work faster, cut costs, and come up with new ideas more quickly. With AI, manufacturers can make their production smoother, improve the quality of their products, and stay ahead in a competitive market.

Today’s manufacturers are challenged to:

- Maintain productivity while minimizing downtime

- Optimize supply chains with predictive analytics

- Produce high-quality products consistently

- Market products digitally to B2B and B2C clients

AI platforms like PlanPost AI are helping industrial businesses streamline operations and marketing efforts, allowing companies to create content, visuals, and campaigns quickly without hiring large creative teams.

Why AI is Essential in Manufacturing

AI is transforming manufacturing across multiple areas:

- Predictive Maintenance

AI systems analyze machine data to predict failures before they occur, reducing downtime and maintenance costs. (World Economic Forum) - Quality Control

AI-powered computer vision can detect defects faster than human inspectors, ensuring consistent, high-quality production. (SAP Insights) - Supply Chain Optimization

AI predicts demand, manages inventory, and streamlines logistics to increase efficiency and reduce waste. (Deloitte Manufacturing Insights) - Energy Management & Sustainability

AI optimizes energy usage, helping factories reduce environmental impact while saving on operational costs. - Digital Marketing & Outreach

Industrial businesses can use AI tools like PlanPost AI to generate professional marketing content, product videos, and targeted ads that reach B2B buyers effectively.

Global Growth and Investment in AI-Powered Manufacturing

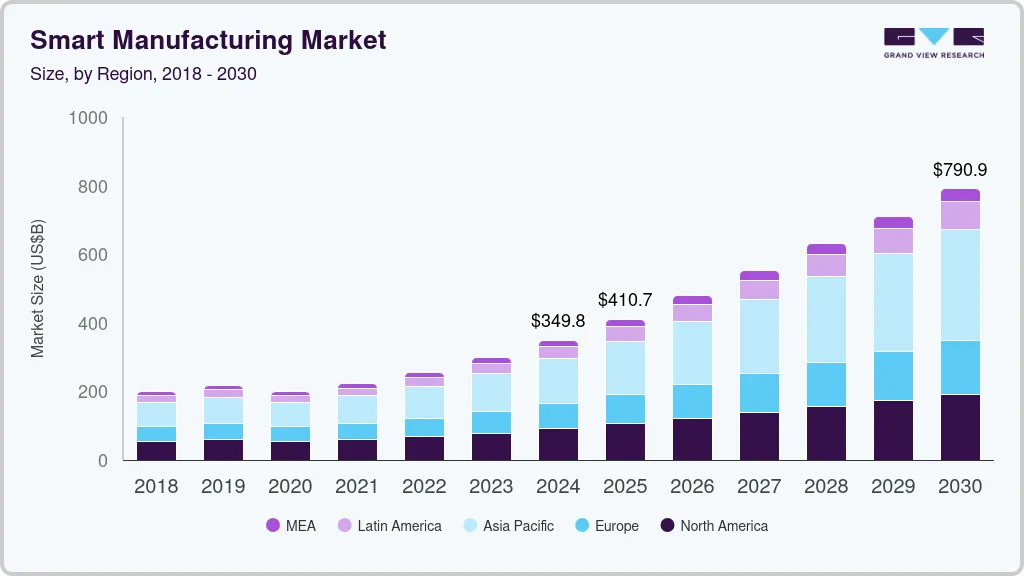

The smart manufacturing market is growing rapidly. According to Grand View Research, the market was valued at $349.8 billion in 2024 and is projected to surpass $410 billion by 2025, with a CAGR of 14% over the next five years.

Leading companies like Bausch + Lomb and Spot & Tango are already implementing AI solutions:

- Bausch + Lomb: Uses AI systems like Atlas AI to predict machinery issues and scale up production efficiently.

- Spot & Tango: Adopted AI-driven agentic systems to automate 60% of purchase orders, improving supply chain reliability. (Business Insider)

Challenges in AI Adoption

While AI offers huge potential, manufacturers must overcome key challenges:

- High Initial Investment: Setting up AI systems requires upfront capital.

- Data Privacy & Security: Connected systems must safeguard sensitive information.

- Skill Gaps: Employees need training in AI, analytics, and system management.

- Integration Complexity: AI must seamlessly integrate with existing machinery and software.

How AI Can Help Marketing & Operations

AI is not just for production—it can enhance digital marketing, content creation, and brand growth:

- Create B2B product visuals and explainer videos quickly

- Generate SEO-optimised content for industrial blogs

- Run targeted Meta Ads campaigns efficiently

- Automate social media posting for industrial brands

Using AI, manufacturers can save time, reduce costs, and scale digital outreach while maintaining consistent quality. (PlanPost AI)

Why AI is a Game-Changer for Industrial Entrepreneur

Why Manufacturing & Industrial Startups Thrive with AI

Entrepreneurs entering the industrial sector today face fierce competition, tight margins, and complex supply chains. However, AI presents unique opportunities to level the playing field:

- Lower Barriers to Entry

Small startups no longer need huge factories or extensive teams to compete. AI tools help automate repetitive tasks, manage inventory, and create marketing campaigns — reducing both manpower and overhead costs. - Rapid Decision-Making

AI systems can analyze production data, predict demand, and recommend process improvements in real time. Startups can make data-driven decisions faster than traditional competitors. - Scalability

AI allows startups to scale operations quickly without proportional increases in staffing. From production optimization to marketing outreach, automation enables efficient growth. - Digital Marketing Advantage

Industrial businesses often struggle to market to niche B2B audiences. AI tools like PlanPost AI can generate professional product visuals, ad copy, and targeted Meta Ads campaigns, giving startups a digital marketing edge.

Facing Problem To Rank your website? Read, How Small Businesses Can Improves Google Rankings with Minimal Effort

How AI Simplifies Operations and Marketing

1. AI in Operations

- Predictive Maintenance: Prevent equipment failure before it occurs.

- Inventory Management: Automatically track stock levels and forecast demand.

- Process Optimization: AI algorithms identify bottlenecks in production and suggest improvements.

- Energy Efficiency: Reduce operational costs through AI-driven energy management.

2. AI in Marketing

Industrial brands can leverage AI to:

- Generate high-quality visuals and product photos without expensive shoots

- Produce AI-written captions, product descriptions, and blogs

- Run targeted Meta Ads campaigns to reach decision-makers in niche industries

- Optimize content for SEO and lead generation

For example, a B2B industrial startup can use AI to generate:

- 10+ product visuals and infographics in minutes

- SEO-friendly blog articles for thought leadership

- AI-generated videos showcasing machinery and processes

- Meta Ads targeting procurement managers and industry buyers

This integration of AI into both operations and marketing helps startups save time, cut costs, and expand reach globally.

Outbound References:

- AI in Industrial Automation – Forbes

- Smart Manufacturing Trends – McKinsey

Real-World AI Use Cases in Industry

- Siemens’ Digital Factory

Siemens has integrated AI to monitor production lines, predict maintenance issues, and optimize workflow. This has resulted in reduced downtime and cost savings. (Siemens Official) - General Electric (GE) Smart Factories

GE uses AI-powered sensors and predictive analytics in their factories to enhance efficiency and prevent equipment failures, saving millions annually. (GE Reports) - Startup Success: Augmentir

Augmentir, an industrial startup, provides AI-powered workforce optimization tools, helping factories train employees faster and increase operational efficiency. (Augmentir) - AI-Powered Marketing Example: PlanPost AI for B2B Industry

Industrial brands can use PlanPost AI to:

- Generate professional social media posts for LinkedIn or Instagram

- Create explainer videos for machinery or products

- Run Meta Ads targeting industrial buyers worldwide

- Generate professional social media posts for LinkedIn or Instagram

Challenges, ROI, and Future Trends of AI in Manufacturing & Industry

Challenges of AI Adoption in Manufacturing

While AI offers significant benefits, manufacturers and industrial startups face several key challenges:

- High Initial Investment

Implementing AI-powered systems such as predictive maintenance tools, smart sensors, and robotics can require substantial upfront capital, which may be a barrier for small and medium-sized enterprises (SMEs). (Forbes – AI in Industrial Automation) - Skill Gaps

Operating AI systems requires skilled employees with knowledge in data analytics, machine learning, and digital tools. Many manufacturers must invest in training programs or hire specialized staff. - Data Security and Privacy

Connected machinery and cloud-based AI systems pose risks of data breaches or misuse. Manufacturers must ensure robust cybersecurity protocols. (Deloitte – AI in Smart Manufacturing) - Integration Complexity

Existing legacy systems may not easily integrate with AI solutions. Proper planning and phased implementation are required to avoid operational disruption. - Measuring ROI

Calculating the return on AI investments can be challenging without clear KPIs and performance metrics.

Maximizing ROI with AI in Manufacturing

Despite challenges, AI adoption delivers tangible returns when implemented strategically:

- Reduced Downtime: Predictive maintenance reduces unexpected failures and repair costs.

- Operational Efficiency: AI-driven analytics optimize production lines, reducing waste and energy usage.

- Marketing & Sales Growth: Using AI platforms like PlanPost AI, industrial brands can generate SEO-friendly content, product visuals, and targeted ads to reach global clients effectively.

- Workforce Optimization: AI helps identify skill gaps, improve employee training, and enhance overall productivity.

Example: A mid-sized machinery company implemented AI for predictive maintenance and inventory forecasting, resulting in 20% reduced downtime and 15% lower operational costs within the first year.

Future Trends in AI for Manufacturing

AI adoption is set to accelerate, driven by technological advancements and industry demands. Key trends include:

1. Digital Twins and Simulation

Digital twins create virtual replicas of machinery and processes, allowing manufacturers to simulate operations, optimize workflows, and predict potential failures. (Siemens – Digital Factory)

2. Predictive Analytics and Smart Supply Chains

AI will continue transforming supply chains by forecasting demand, monitoring logistics, and managing inventory with high precision.

3. AI-Powered Quality Control

Advanced computer vision and sensors will detect defects in real time, reducing wastage and ensuring consistent product quality.

4. Energy Efficiency and Sustainability

AI-driven energy management systems help factories reduce carbon footprint and meet global sustainability standards. (SAP – AI in Manufacturing)

5. Industrial Marketing Innovation

AI platforms allow industrial companies to create marketing content faster, run data-driven campaigns, and engage niche B2B audiences worldwide. (PlanPost AI)

Real-World Industrial AI Applications

- Siemens Smart Factory: AI monitors production lines, predicts equipment issues, and reduces downtime.

- GE Digital Manufacturing: Predictive analytics and sensors optimize operations and improve efficiency.

- Augmentir Industrial Startup: Provides AI-powered workforce optimization tools for training and performance tracking.

These examples demonstrate that AI adoption improves both operational efficiency and market competitiveness, making it a critical tool for the modern manufacturing industry.

Innovation, Marketing, and Practical AI Implementation in Manufacturing

AI-Driven Innovation in Manufacturing

The integration of AI is driving unprecedented innovation in the manufacturing and industrial sector. From smart factories to digital supply chains, AI enables businesses to rethink traditional operations:

- Digital Twins & Simulation

Digital twins allow manufacturers to create virtual replicas of machinery and production lines, enabling simulations to test efficiency, predict equipment failure, and reduce downtime. (Siemens – Digital Factory) - Smart Robotics & Automation

AI-powered robots perform repetitive tasks with high precision and consistency, reducing human error and improving safety on the shop floor. - AI-Powered Quality Assurance

Advanced computer vision systems monitor products in real time, detecting defects and ensuring consistent high quality, minimizing returns and customer dissatisfaction. - Predictive Supply Chain Management

AI algorithms analyze market trends, demand patterns, and logistics data to streamline inventory management, reduce waste, and enhance delivery reliability. - Sustainable Manufacturing

AI tools monitor energy consumption, emissions, and resource use to support eco-friendly practices, making factories more sustainable and cost-efficient. (SAP – AI in Manufacturing)

Marketing Case Studies: AI in Industrial Promotion

Industrial companies often underestimate the importance of digital marketing, but AI is changing that. Here are some real-world examples:

Case Study 1: Siemens Industrial Marketing

Siemens leverages AI to create content, visuals, and campaigns for B2B audiences. AI assists in generating professional product images, explainer videos, and targeted campaigns to decision-makers in manufacturing industries. (Siemens Marketing AI)

Case Study 2: Augmentir – AI for Startups

Augmentir, an industrial startup, used AI tools to train workers, optimize workflows, and market solutions globally. They combined predictive analytics with AI-generated social media content to reach industrial clients efficiently. (Augmentir)

Case Study 3: Using PlanPost AI for Industrial Content

Industrial SMEs can use PlanPost AI to:

- Generate product visuals and explainer videos

- Create SEO-friendly blog content

- Automate social media posts and Meta Ads campaigns

- Target specific industrial decision-makers globally

This demonstrates that AI is not just for production—it’s also a powerful tool for marketing and business growth in the manufacturing sector.

Practical Tips for Implementing AI in Manufacturing

For startups, SMEs, and industrial entrepreneurs, implementing AI can be overwhelming. Here’s a step-by-step practical guide:

- Assess Your Needs

Identify areas where AI can add the most value, such as predictive maintenance, quality control, or marketing automation. - Start Small

Begin with a pilot project to test AI tools in a specific operation before scaling company-wide. - Leverage AI Platforms

Platforms like PlanPost AI simplify content creation, marketing, and campaign automation, saving time and cost. - Train Your Workforce

Invest in employee training programs to bridge skill gaps in AI, data analytics, and digital tools. - Monitor ROI

Track KPIs like downtime reduction, production efficiency, lead generation, and marketing engagement to evaluate AI performance. - Ensure Security and Compliance

Implement robust cybersecurity and data privacy measures when deploying AI solutions.

Frequently Asked Questions (FAQ) – AI in Manufacturing & Industry

1. How can AI improve efficiency in manufacturing?

AI automates repetitive tasks, predicts equipment failures, optimizes supply chains, and ensures consistent product quality. Using AI tools like PlanPost AI, manufacturers can also generate marketing content, reducing manual effort and increasing reach.

2. What are the key AI applications in industrial operations?

- Predictive maintenance

- Smart quality control with computer vision

- Energy optimization

- Supply chain and inventory management

- Process automation and robotics

3. Is AI suitable for small and medium-sized industrial businesses?

Absolutely. AI platforms like PlanPost AI allow SMEs to create marketing campaigns, visuals, and ads while optimizing operational processes without requiring huge capital or teams.

4. How does AI help industrial marketing?

AI can generate professional product images, videos, SEO-friendly blogs, and Meta Ads campaigns. It also helps target niche B2B buyers efficiently, increasing brand visibility and lead generation.

5. What challenges should industrial companies anticipate with AI adoption?

- High initial setup costs

- Workforce skill gaps

- Data privacy and cybersecurity concerns

- Integration complexity with existing systems

6. How can companies measure ROI from AI?

Track metrics such as reduced downtime, improved production efficiency, cost savings, marketing engagement, and lead generation. Pilot programs often provide measurable results before full-scale implementation.

7. Can AI contribute to sustainability in manufacturing?

Yes. AI optimizes energy consumption, reduces waste, and monitors emissions, supporting eco-friendly manufacturing practices. (SAP – AI in Manufacturing)

The manufacturing and industrial world is going through an exciting change. From traditional assembly lines to modern smart factories, companies are now using AI tools for the manufacturing industry to work faster, cut costs, and come up with new ideas more quickly. With AI, manufacturers can make their production smoother, improve the quality of their products, and stay ahead in a competitive market. You can explore and try these AI-powered solutions yourself at PlanPost AI.